Modern Dimensional Letter Manufacturing Techniques: Your Comprehensive Guide to the World of 3D Signage

In today’s highly competitive business world, signs are no longer just a way to display a brand name; they have become a fundamental element in shaping visual identity and attracting customer attention. Among the most prominent and impactful types of signage, dimensional letters reign supreme in elegance and appeal. With tremendous technological advancements, dimensional letter manufacturing techniques have taken a quantum leap, offering endless options in terms of materials, precision, and innovative designs. In this comprehensive article, we will delve into the depths of this exciting world, showcasing the latest industry methods and materials to provide an integrated guide for business owners and designers alike.

The Growing Importance of Dimensional Letters in the World of Advertising

Before diving into the technical details, it’s essential to understand the reason for the growing importance of dimensional letter signs. They add an extra dimension to the sign, creating visual contrast and shadows that bring depth and life to the design. This three-dimensional aspect not only attracts the eye but also conveys professionalism, quality, and stability—implicit messages that help build customer trust in the brand. Whether illuminated with eye-catching light at night or carefully polished to elegantly reflect daylight, dimensional letters ensure a lasting and unforgettable impression.

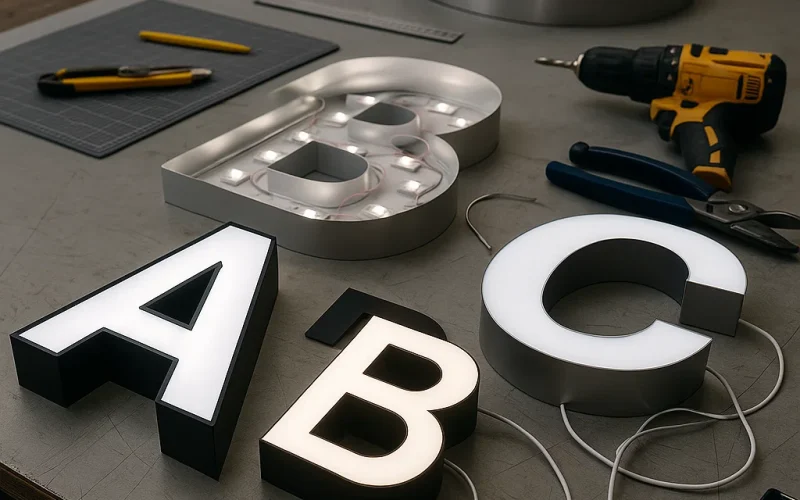

Exploring the Most Prominent Dimensional Letter Manufacturing Techniques

The methods used to create these artistic pieces are diverse, with each technique giving the final product unique characteristics. It can be said that modern dimensional letter manufacturing techniques combine precise craftsmanship with advanced machinery that ensures production speed and standardization.

1. Laser Cutting: This technique is one of the most accurate and fastest ways to cut various material sheets like acrylic (plastic) and steel. A high-energy laser beam, controlled by a computer, is directed to cut designs with extreme precision, allowing for the execution of intricate details and fine logos with polished, clean edges without the need for additional finishing.

2. CNC Routing: CNC machines are primarily used with thicker and harder materials such as Zincore, aluminum, and some types of plastic and wood. This technology relies on a rotating cutting tool (a router) that moves on multiple axes based on a digital design, enabling it to carve and shape letters with varying depths and thicknesses, making it ideal for producing large-scale letters.

3. Metal Bending and Fabrication: After the letter face is cut, the next stage is forming the sides (the return). Specialized automatic bending machines are used to precisely bend metal strips (like steel, Zincore, and aluminum) to perfectly match the curves of the letter face. These sides are then welded to the face using advanced welding techniques such as laser welding or argon welding, which ensures the structure’s durability and strength.

4. 3D Printing: Although still an emerging technology in the field of large-scale signage, 3D printing is beginning to find its way into manufacturing complex models and small logos. This technology allows for immense design freedom and the ability to produce shapes that were impossible to manufacture with traditional methods.

Materials Used: The Backbone of Quality Dimensional Letters

Choosing the right material is just as important as choosing the design. Each material has its own properties that affect the appearance, durability, cost, and maintenance method. Understanding these properties helps in making an informed decision that serves your business and aesthetic goals.

| Material | Key Features | Common Uses | Average Lifespan (Outdoor) |

| Acrylic | Glossy and modern look, high light permeability, wide variety of colors, lightweight. | Fully illuminated letters (face and sides), storefronts, indoor signs. | 5 – 7 years |

| Stainless Steel | Extreme luxury and elegance, high resistance to rust and weather, exceptional durability. | Non-illuminated letters, backlit (halo) letters, signs for major corporations and banks. | 10+ years |

| Zincore | Treated rust-resistant metal, excellent paintability in any color, reasonable cost. | Illuminated and non-illuminated letters, a practical alternative to steel in many applications. | 7 – 10 years |

| Aluminum | Very lightweight, corrosion-resistant, easy to shape and paint. | Large-scale letters, signs hung at heights, sign structures. | 10+ years |

| Brass | Classic, luxurious appearance, develops a natural patina over time that enhances its beauty. | Signs for law offices, luxury hotels, historic buildings. | 15+ years |

| Foam | Extremely lightweight, low cost, easy to install. | Temporary exhibition signs, interior decorations, non-illuminated letters. | 1 – 3 years (indoor) |

This table provides an overview of the most prominent materials. The final choice depends on the available budget, the location (indoor or outdoor), and the brand’s visual identity. Understanding the dimensional letter manufacturing techniques associated with each material is the key to achieving the desired result.

The World of Lighting: Breathing Life into Dimensional Letters

Lighting plays a pivotal role in enhancing the beauty of dimensional letters, especially after sunset. LED technology is currently dominant in this field due to its high energy efficiency, long operational life, and color variety.

Types of Dimensional Letter Lighting:

- Front-Lit: The face of the letter is made from a light-permeable material (often acrylic), and LED modules are placed inside the letter to illuminate the face directly. This is the most common method for its high visibility.

- Back-Lit/Halo: The face and sides of the letter are made of an opaque material (like steel or Zincore), and the light is directed towards the back wall, creating an elegant and distinctive halo effect around the letter.

- Side-Lit: The sides of the letter are made of acrylic while the face is opaque, causing the light to shine only from the sides, which is a unique and attractive effect.

- Open-Face: The face of the letter is left open or covered with clear acrylic to reveal the internal lighting units (often neon or classic-style LED bulbs) directly, giving it a vintage feel.

Combining advanced dimensional letter manufacturing techniques with innovative lighting options opens up infinite possibilities for creativity.

Comparison Between Common Dimensional Letter Manufacturing Techniques

To provide a clearer picture, here is a practical comparison between the most prominent techniques and materials used, which should be considered when planning a new sign project.

| Feature | Illuminated Acrylic Letters | Backlit (Halo) Steel Letters | Painted Zincore Letters |

| Overall Appearance | Modern, bright, eye-catching | Luxurious, elegant, sophisticated | Practical, color-customizable |

| Visibility (at night) | Excellent | Very good | Depends on external lighting |

| Durability | Good | Excellent | Excellent |

| Cost | Medium | High | Medium to low |

| Maintenance | Periodic cleaning of the face | Dust removal from the back | May need repainting after years |

| Best Application | Storefronts, restaurants, malls | Corporations, hotels, luxury facades | Shops, warehouses, institutions |

The Future of Dimensional Letter Manufacturing Techniques

Development never stops, and the future of dimensional letter manufacturing techniques looks bright. We can expect greater integration of smart technologies, such as letters whose colors can be changed via mobile apps or that interact with passersby. The trend towards sustainable and environmentally friendly materials will also increase, with the development of new recyclable materials with a lower carbon footprint. Precision will continue to improve with the evolution of cutting and forming machines, opening the door to bolder and more complex designs.

In conclusion, the manufacturing of dimensional letters is no longer just a process of cutting and pasting; it is an art and a science that require a deep understanding of materials, precision in execution, and creativity in design. Investing in a high-quality sign that uses the best dimensional letter manufacturing techniques is a direct investment in your brand’s identity and its ability to stand out in a crowded market. By choosing the right partner, materials, and technology, you will ensure that your business facade is not just an address, but an open invitation for customers to discover the excellence and quality you offer.

العربية

العربية